ROL/Statga, the Swedish-capital manufacturer of adjustable height tables, is expanding its production capacities in Šiauliai. The company has completed the construction of a new factory and begun the installation of a robotized table production line. Investments in this smart factory will amount to EUR 11.9 million by 2018.

“When choosing an investment location for the new-generation robotized factory, ROL Group’s shareholders discussed opportunities in Poland and Slovakia. The main factors influencing the expansion in Šiauliai are the expertise of local specialists, their engagement, the desire to bring production processes in an existing factory to a technically advanced level, and a convenient geographical location allowing for the smooth export of products to target markets,” Rytis Dijokas, manager of ROL/Statga, said.

“When the development opportunities in Šiauliai were being considered, the involvement of representatives from Šiauliai City Municipality and their willingness to help with the expansion contributed significantly. So although there were sufficient reasons for investing in Lithuania, we had to fight for a favourable decision from the shareholders,” Mr Dijokas added.

The company now plans to recruit 10 highly qualified specialists for the smart factory. At present, the employees are improving their knowledge of project management, operating robotic machines, and LEAN implementation. Estimated investments in this training amount to more than EUR 250,000.

“We are constantly striving to attract and retain the best specialists, and we look after their safety and well-being. Investment in air filters alone was about EUR 312,000. A total of 200 people use the modern factory canteen every day, where they enjoy lunches that are 50% subsidised by the company,” Mr Dijokas said.

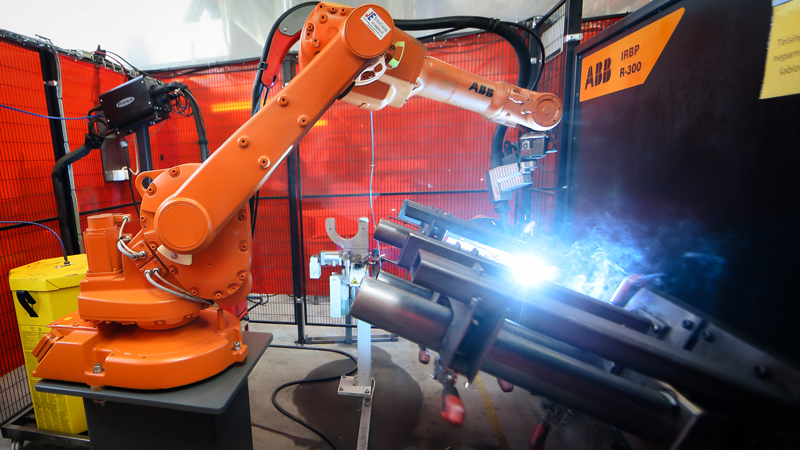

The specifics of the factory mean that highly qualified specialists are needed. The factory will be almost fully robotized, so practically all of the production process will be performed by machines programmed and maintained by people. In other words, the raw materials fed into the mechanisms at the start of the production cycle will at the end of the cycle become a finished product without physical human intervention. The company’s engineers together with international automation solution partners did most of the work in designing the automated assembly lines. The international partners were surprised by the competences of the local specialists.

The development of ROL Group in Šiauliai with its highly impressive future production plans shows that Lithuania’s regions have the potential to attract high value-added projects. One of the strategic goals of the government is regional development, so the government is delighted with such investment plans,” Prime Minister Saulius Skvernelis said.

“Investment in production will give an impetus to the city not only in economic terms but also in social terms. The fact that large investments come not only to Vilnius or Kaunas creates the image of an attractive environment for living that is particularly important to Šiauliai today. Furthermore, the company is moving hand-in-hand with the fourth industrial revolution and is looking ahead to the future by investing in technological renewal,” Minister of Economy Mindaugas Sinkevičius said.

“The production capacity to be built by the Swedish company is an excellent example of recent production trends. So far, there are just a few such plants in Lithuania, but their number should increase in the near future. They do not bring hundreds of jobs to the market, but the country’s educational institutions must be aware now and think about the competences of future highly qualified specialists who will be needed to work in such factories,” Mantas Katinas, director general of Invest Lithuania, said.

At present, the factory in Šiauliai has 415 employees.

Source - InvestLithuania.com.